mes系统英文介绍,Introduction to MES System

时间:2024-10-21 来源:网络 人气:

Introduction to MES System

Manufacturing Execution System (MES) is a critical component in the realm of industrial automation and production management. This article aims to provide an in-depth introduction to MES systems, their significance, and how they contribute to the efficiency and effectiveness of modern manufacturing processes.

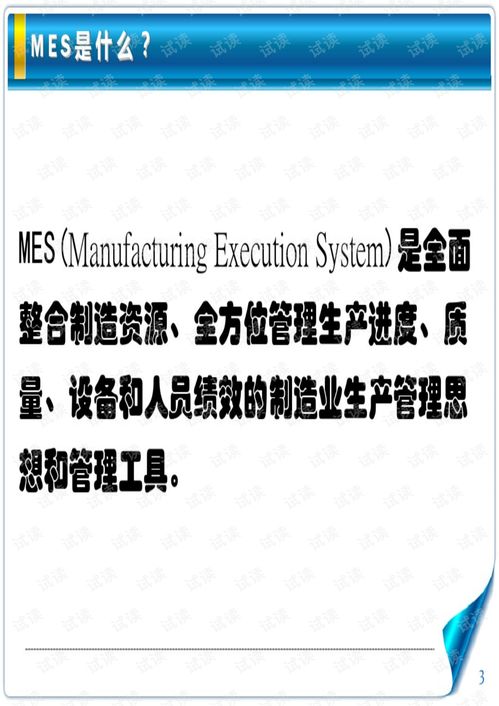

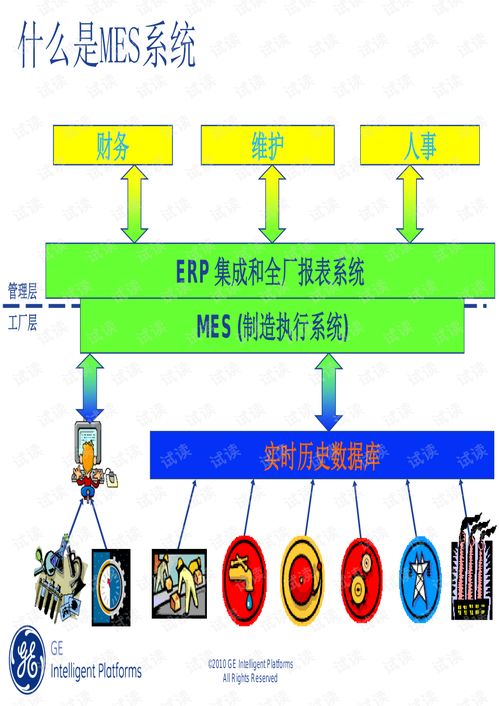

What is MES?

MES, which stands for Manufacturing Execution System, is a software application that integrates with enterprise resource planning (ERP) systems and provides real-time visibility and control of the manufacturing process. It serves as a bridge between the strategic planning level of ERP and the operational level of the shop floor.

Key Functions of MES

MES systems are designed to manage and optimize various aspects of the manufacturing process. Some of the key functions include:

Production Scheduling and Dispatching: MES helps in planning and scheduling production activities, ensuring that resources are allocated efficiently.

Real-Time Data Collection: MES systems collect real-time data from the shop floor, providing insights into production performance and efficiency.

Quality Control: MES enables manufacturers to monitor and control the quality of products throughout the production process.

Resource Management: MES optimizes the use of resources such as labor, materials, and equipment.

Inventory Management: MES helps in managing inventory levels, reducing waste, and improving supply chain efficiency.

Benefits of MES Systems

Implementing an MES system can bring numerous benefits to a manufacturing organization, including:

Increased Productivity: MES systems help in streamlining production processes, reducing downtime, and improving overall productivity.

Improved Quality: By monitoring and controlling the quality of products throughout the production process, MES systems help in reducing defects and improving product quality.

Reduced Costs: MES systems optimize resource utilization, reduce waste, and improve supply chain efficiency, leading to cost savings.

Better Decision Making: Real-time data provided by MES systems enables managers to make informed decisions, leading to improved operational performance.

Increased Flexibility: MES systems allow manufacturers to respond quickly to changes in demand and production requirements.

How MES Systems Work

MES systems work by integrating with various manufacturing processes and systems. Here's a simplified overview of how they function:

Input: The MES system receives production orders and other relevant data from the ERP system.

Processing: The system processes the data, schedules production activities, and dispatches tasks to the shop floor.

Execution: The shop floor personnel execute the tasks, and the MES system collects real-time data on production performance.

Analysis: The system analyzes the collected data to provide insights into production performance, identify bottlenecks, and suggest improvements.

Feedback: The MES system provides feedback to the ERP system, ensuring that the production process is aligned with the strategic goals of the organization.

Challenges and Considerations

While MES systems offer numerous benefits, there are also challenges and considerations to keep in mind:

Implementation Complexity: Implementing an MES system can be complex and requires careful planning and execution.

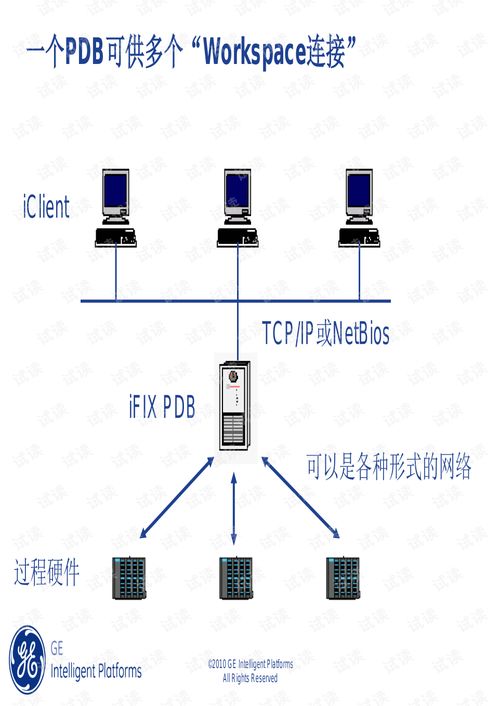

Integration: Ensuring seamless integration with existing systems and processes is crucial for the success of an MES implementation.

Change Management: Implementing an MES system often requires changes in processes and training for employees, which can be challenging.

Cost: The cost of implementing and maintaining an MES system can be significant, especially for small and medium-sized enterprises.

Conclusion

MES systems play a vital role in modern manufacturing by providing real-time visibility and control of the production process. By optimizing production activities, improving quality, and reducing costs, MES systems contribute to the overall success of manufacturing organizations. As the manufacturing industry continues to evolve, the importance of MES systems is expected to grow, making them an essential tool for manufacturers seeking to stay competitive in the global market.

Tags:

MES system, manufacturing execution system, production management, industrial automation, real-time data, quality control, resource

相关推荐

教程资讯

教程资讯排行